Important Properties and Uses of Food Grade Polyethylene Sheeting

By:Admin

Introduction:

In a significant development for the food packaging industry, an innovative food grade polyethylene sheeting has emerged as a game-changer. This groundbreaking product is poised to revolutionize the way food is packaged, stored, and transported, ensuring maximum freshness and safety for consumers worldwide. Developed by a leading company committed to excellence in food packaging solutions, this cutting-edge material demonstrates a remarkable blend of durability, versatility, and sustainability.

[Company Name], a renowned pioneer in the food packaging industry, has dedicated decades to research and development in order to bring this revolutionary food grade polyethylene sheeting to market. With a strong focus on customer satisfaction, the company has consistently delivered innovative solutions that meet the ever-evolving needs of the industry. This latest breakthrough underscores their commitment to developing environmentally-responsible packaging materials without compromising on quality and functionality.

Body:

1. Importance of Food Grade Polyethylene Sheeting:

Food safety is paramount in the packaging industry, and the introduction of food grade polyethylene sheeting is a significant step towards ensuring the highest standards. Polyethylene, a type of plastic, has been used extensively in various applications. However, the development of food grade polyethylene sheeting guarantees that the material adheres to strict regulations and guidelines set by food regulatory bodies. This ensures that the sheeting does not contaminate the food it comes into contact with, maintaining its taste, quality, and nutritional value.

2. Key Advantages of Food Grade Polyethylene Sheeting:

Food grade polyethylene sheeting offers several key advantages that make it an ideal choice for food packaging:

a) Durability and Strength: The material is highly resistant to tearing, puncturing, and moisture, ensuring that the food remains fresh and protected during transportation and storage.

b) Versatility: Food grade polyethylene sheeting can be used for a wide range of food packaging applications, including wrapping perishable goods, lining containers, or even creating custom-sized bags as per specific requirements.

c) Heat Resistance: The sheeting's ability to withstand high temperatures makes it suitable for packaging hot food items, such as freshly-cooked meals or hot beverages.

d) Tamper Resistance: One of the critical features of food grade polyethylene sheeting is its ability to detect tampering. The material can be designed with features that show evidence of any unauthorized access, ensuring food safety and consumer trust.

3. Sustainability and Environmental Impact:

With a growing emphasis on sustainability and eco-friendly packaging, food grade polyethylene sheeting is a clear winner. Made from recyclable materials, it helps reduce plastic waste and promotes a circular economy. Additionally, the sheeting can be produced with bio-based additives, further reducing its carbon footprint. The incorporation of such sustainable features aligns with the company's commitment to responsible packaging and minimizing environmental impact.

4. Regulatory Compliance and Safety:

Compliance with food safety regulations is a primary concern for the food packaging industry. Companies using food grade polyethylene sheeting can enjoy peace of mind, knowing that their packaging material adheres to strict food safety standards. The sheeting undergoes rigorous testing and meets industry benchmarks to ensure it is safe for direct food contact, providing consumers with the assurance of a reliable and secure packaging solution.

Conclusion:

The introduction of food grade polyethylene sheeting marks a significant milestone in the evolution of food packaging. With its durability, versatility, and commitment to sustainability, this innovative product offers a comprehensive and reliable solution for the food industry. [Company Name]'s dedication to delivering cutting-edge food packaging solutions ensures that consumers can trust the safety and quality of the products they consume. As the demand for efficient and eco-friendly packaging continues to rise, food grade polyethylene sheeting provides a remarkable solution that paves the way for a more sustainable future.

Company News & Blog

High-Density Polyethylene (HDPE) Sheet for Diverse Applications: Latest News Update

Grey HDPE Sheet: A Versatile Solution for Various ApplicationsIn today's rapidly changing industrial landscape, companies are constantly seeking innovative solutions to optimize production processes and improve product quality. One such solution that has quickly gained popularity is the grey HDPE sheet. Renowned for its versatility, durability, and wide-ranging applications, the grey HDPE sheet is becoming an indispensable asset for countless industries worldwide.HDPE, or High-Density Polyethylene, is a thermoplastic polymer renowned for its exceptional strength and durability. These properties make it an ideal choice for numerous applications in diverse industries, including construction, food packaging, healthcare, and transportation.The grey HDPE sheet, in particular, has captured the attention of manufacturers due to its unique characteristics. Its striking grey color provides a sleek and modern aesthetic, often preferred in contemporary designs. Additionally, the material's opacity ensures that any discoloration or surface blemishes are easily masked, promoting a visually appealing end product.One of the primary advantages of the grey HDPE sheet is its unparalleled resistance to chemicals, moisture, and UV radiation. These properties make it suitable for numerous outdoor applications, including signage, playground equipment, and agricultural structures. The grey HDPE sheet's resistance to moisture allows it to withstand harsh weather conditions, ensuring its longevity and reducing maintenance costs. Furthermore, its excellent chemical resistance enables it to withstand exposure to various solvents and chemicals, making it an ideal choice for industrial storage areas and laboratories.The grey HDPE sheet's remarkable mechanical properties contribute to its widespread usage. It possesses an exceptional tensile strength, allowing it to withstand heavy loads and impact resistance, making it ideal for applications such as truck bed liners and equipment protection. Moreover, its high flexibility and low coefficient of friction make it an excellent choice for applications requiring low friction properties, such as conveyor systems and sliding components.In addition to its exceptional physical properties, the grey HDPE sheet boasts excellent thermal insulation properties. Its low thermal conductivity ensures efficient energy conservation, making it a valuable asset for industries seeking to reduce their carbon footprint. From roofing insulation to thermal barriers, the grey HDPE sheet offers a cost-effective solution for maintaining optimal temperature conditions in various settings.Recognizing the potential of the grey HDPE sheet, leading manufacturers, such as {Company Name}, have dedicated their expertise to produce high-quality grey HDPE sheets tailored to meet the specific requirements of their customers. With state-of-the-art manufacturing facilities and cutting-edge technology, {Company Name} has emerged as a leader in the production of grey HDPE sheets.{Company Name}, a globally renowned company in the plastics industry, prides itself on delivering premium quality grey HDPE sheets. Backed by years of company experience and a team of skilled professionals, they strive to provide innovative solutions to businesses across numerous sectors.At {Company Name}, quality is a top priority. Every grey HDPE sheet undergoes rigorous testing and inspection to ensure its conformity to industry standards and customer expectations. By adhering to strict quality control protocols, {Company Name} guarantees that their grey HDPE sheets meet the highest performance requirements.Furthermore, {Company Name} understands the importance of customization. With the ability to provide grey HDPE sheets in various thicknesses, sizes, and finishes, they can fulfill specific customer demands and applications. By working closely with their clients, {Company Name} aims to provide tailored solutions that address individual needs, fostering lasting partnerships.In conclusion, the grey HDPE sheet has emerged as a versatile and indispensable solution for a wide range of industries. With its exceptional properties in terms of strength, durability, chemical resistance, and thermal insulation, it has become a preferred choice for numerous applications worldwide. Companies like {Company Name} are at the forefront of manufacturing high-quality grey HDPE sheets, catering to the diverse needs of businesses across various sectors. As the industrial landscape continues to evolve, the grey HDPE sheet will undoubtedly play a pivotal role in driving innovation and optimizing production processes for years to come.

Understanding Orthosis: Definition and Meaning as per Medical Terminology

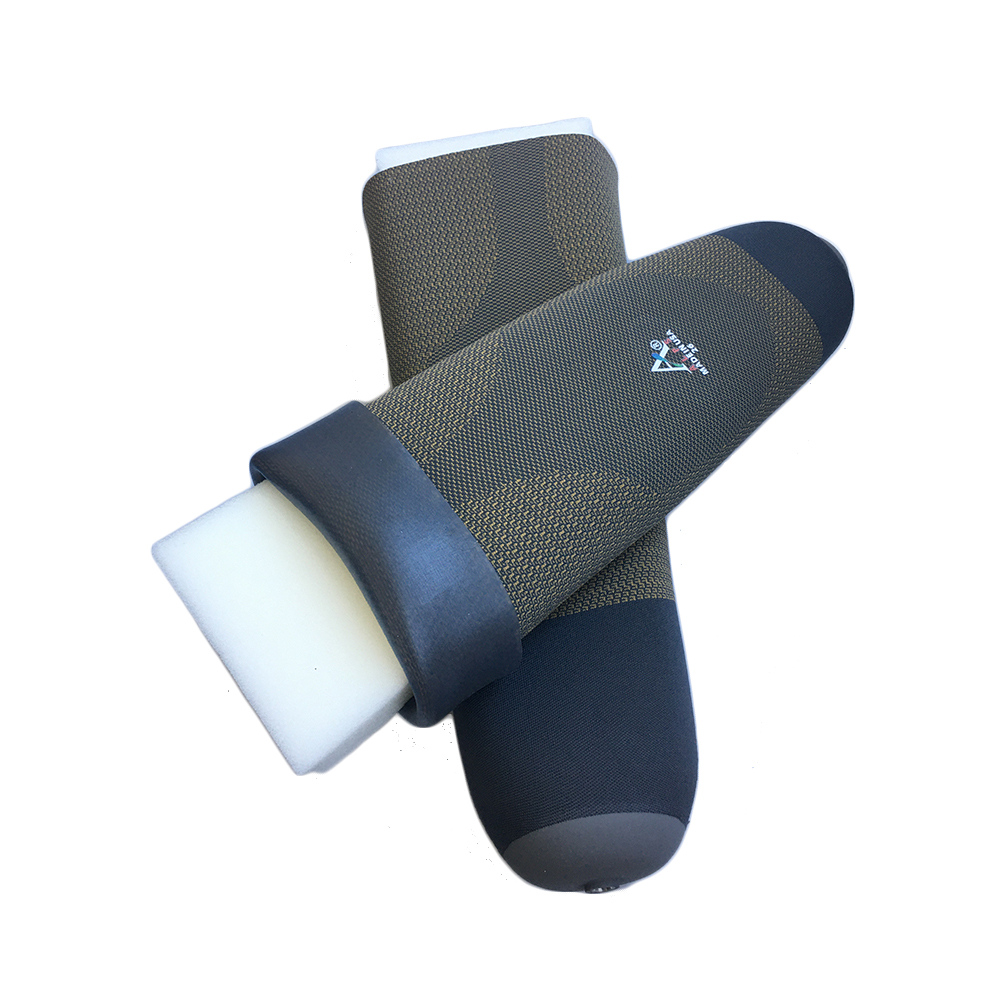

article about the benefits of orthosis knee braces.Orthosis Knee Braces: The Ultimate Solution to Joint Pain Orthosis knee braces have become a popular solution for people suffering from knee injuries and conditions such as arthritis. These braces provide support to the knee and aid in recovery after surgery. They are also instrumental in reducing the pain associated with knee injuries and other related conditions. Orthosis is a medical term that refers to the use of various supportive devices, such as braces, splints, and casts, to aid in the recovery process after an injury or surgery. Orthosis knee braces, in particular, are designed to provide support to the knee, reduce stress on the joint, and allow for proper movement of the leg. Many people experience knee pain due to osteoarthritis or other conditions that cause a gradual erosion of the cartilage in the knee joint. Orthosis knee braces are an effective way of reducing the pain associated with such conditions and improving mobility and flexibility. One of the leading brands in the market, (name removed), has been providing high-quality orthosis knee braces to patients for many years. Their braces are designed with the latest technology to ensure patients get optimal support, comfort and pain relief. One of the outstanding features of orthosis knee braces is the adjustable nature of the joint, which allows for customization depending on the condition of the knee. This adjustability allows for the braces to be molded to a patient’s exact requirements, resulting in a perfect fit and the most effective support possible. Apart from being adjustable, orthosis knee braces are also made of lightweight and breathable materials. This design ensures maximum comfort during use, and also prevents sweating and skin irritation, which can often occur with heavier, non-breathable materials that can lead to bad odours and skin issues. Orthosis knee braces come in different types to suit different knee conditions. Some braces provide support to the patella, while others are designed to distribute the weight of the body equally. With the right Orthosis knee brace for your specific condition, one can get the pain relief they need to support an active lifestyle. One of the most significant benefits of orthosis knee braces is that they can help prevent further damage to the knee joint. After an injury or surgery, the knee joint can be vulnerable and in need of support to avoid further damage. Orthosis knee braces provide the necessary support to allow the knee to heal and recover without any additional damage or strain. The use of orthosis knee braces isn't limited to people recovering from injuries or surgeries. They can be used also keeping your knees healthy and injury-free during physical activities with the help of a preventive and proactive mentality. The braces can provide support and protection to the knee during intense workouts, contact sports, and other such activities. In conclusion, orthosis knee braces are an effective and safe way of providing support to the knee, reducing pain, and minimizing the risk of further damage. By choosing the right orthosis knee brace for your specific condition, you can improve your mobility, flexibility, and overall quality of life. With the numerous benefits associated with orthosis knee braces, it's no wonder they have become a popular solution for anyone suffering from knee pain.

Advanced Prosthetic Socket Making Devices for Effective Rehabilitation

Rehabilitation Equipment Prosthetics & Orthotics Device from [Brand Name] Makes a Difference in the Lives of AmputeesFor amputees, life can be challenging and pose several barriers. Losing a limb can lead to a loss of independence, decreased mobility, and a feeling of isolation. However, with modern technology, prosthetics have come a long way to help amputees regain independence and integrate with society once more. One essential part of a prosthetic is the socket, which provides comfort, support, and attaches the prosthetic to the residual limb. The Rehabilitation Equipment Prosthetics & Orthotics Device from [Brand Name] makes it easy to create a comfortable socket for amputees.[Brand Name] is a prominent player in the prosthetic and orthotic field, having been in business for over two decades. They help amputees around the world gain independence and lead a fulfilling life. Known for their cutting-edge designs and seamless technology, [Brand Name] has been instrumental in changing the lives of countless amputees by providing prosthetics that are both comfortable and functional.The latest offering by [Brand Name] is the Rehabilitation Equipment Prosthetics & Orthotics Device, a revolutionary device that can make a significant difference in the lives of amputees. This device uses an innovative blend of engineering and technological advancements to create prosthetic sockets that are durable, comfortable, and personalized to each patient's needs.The [Brand Name] Rehabilitation Equipment Prosthetics & Orthotics Device makes it easy for technicians to create prosthetic sockets that are perfectly suited to the patient's needs. The device features an intuitive interface that assists in socket measurements, making the process accurate and smooth. The software allows the technician to adjust the socket design during the casting process, ensuring that the final product is a perfect fit and comfortable to wear. The software also allows for customization of the socket's design, ensuring that it fits the patient's lifestyle and preferences. Once the final design is complete, the casting can be 3D printed, ensuring a precise and comfortable fit for patients.One of the key benefits of the Rehabilitation Equipment Prosthetics & Orthotics Device is its versatility. This device can create sockets for lower limbs, upper limbs, and even for individuals with quadriplegia. The device is easy to operate, making it accessible to technicians of all skill levels. Additionally, the operating software comes with extensive training, ensuring that technicians can master the device and get the most out of it.Speaking about the device, the CEO of [Brand Name], [Name], said, "we are proud to offer this cutting-edge technology to our customers. The Rehabilitation Equipment Prosthetics & Orthotics Device is a game-changer in the field of prosthetics. Our commitment to our customer's well-being and independence led us to develop a device that can deliver comfortable, durable prosthetics. The device combines our experience of over two decades with modern technology to create prosthetics that are not only functional but also provide comfort to our patients."The Rehabilitation Equipment Prosthetics & Orthotics Device from [Brand Name] has been instrumental in improving the lives of amputees. It has made creating customized prosthetic sockets more accessible and affordable. As a result, more amputees can lead productive and fulfilling lives, without any limitations.In conclusion, the Rehabilitation Equipment Prosthetics & Orthotics Device from [Brand Name] is a revolutionary device that is changing the lives of amputees. The device's innovative design, combined with [Brand Name]'s experience, makes it easy to create prosthetic sockets that provide comfort, support, and help amputees regain their independence. With the device's versatility, ease of use, and customization options, amputees can now look forward to a brighter future with confidence.

How to Properly Use a Pistol Cable Lock: A Step-by-Step Guide for Revolvers and Automatic Handguns

Most gun owners know that safety is the most important aspect of owning a firearm. And one of the best ways to ensure your firearm is kept secure is by using a cable lock. A cable lock is a gun safety device made of a durable steel cable that locks the action of your firearm. This prevents the gun from being loaded, fired, or disassembled.The pistol cable lock is a versatile option that works well with both revolvers and automatic handguns. In this article, we will discuss step-by-step how to use a cable lock with both revolver and automatic pistols.Using a Cable Lock with RevolversFollow these steps to use a cable lock with a revolver:Step 1 - Unload the RevolverBefore using a cable lock with a revolver, ensure that your gun is unloaded. Remove all bullets from the revolver and make sure the revolver is empty.Step 2 - Insert Cable into the RevolverNow take your cable lock, and insert one end of the cable into the cylinder of the revolver. The cable should be fed through the cylinder to emerge from the opposite end.Step 3 - Secure the Cable LockNext, take the other end of the cable and pass it through the loop. The loop should pass through the cylinder and through the frame of the revolver. Tighten the cable using the lock and insert the key to secure it.Using a Cable Lock with AutomaticsFollow these steps to use a cable lock with an automatic:Step 1 - Unload the PistolBefore using a cable lock with an automatic, ensure that your gun is unloaded. Remove the magazine from the gun and ensure that the chamber is empty.Step 2 - Insert Cable into PistolNow take your cable lock and insert one end of the cable into the barrel of the pistol. The cable should be fed through the barrel and should emerge from the opposite end.Step 3 - Tighten the Cable LockNext, take the other end of the cable and pass it through the loop. The loop should pass through the slide of the pistol and the frame. Tighten the cable using the lock and insert the key to secure it.Machining Drive-By-Wire Spring LockMachining Drive-By-Wire Spring Lock is a type of gun safety device that uses a spring lock mechanism. This type of lock is commonly used in rifles and shotguns. The mechanism works by placing a pin in the firing pin channel, thereby preventing the action from being able to discharge. This type of lock is also useful for preventing unauthorized access to firearms. ConclusionUsing a cable lock is essential for keeping your firearm safe. By using the steps mentioned above, you can ensure that your revolver or automatic pistol is secure and cannot be loaded, fired, or disassembled. Additionally, using a Machining Drive-By-Wire Spring Lock is another effective option for gun safety. Remember to always store your firearms safely and keep them out of the hands of children.

Orthotic Hip Joint: A Revolutionary Solution for Enhanced Mobility and Comfort

Title: Innovative Orthotic Hip Joint Revolutionizes Mobility for PatientsIntroduction:[Company Name], a renowned leader in medical device innovation, has recently developed an groundbreaking orthotic hip joint. Designed to enhance mobility and restore freedom of movement for patients suffering from hip conditions, this innovative solution represents a significant breakthrough in orthopedic technology. With its advanced features and unparalleled functionality, the orthotic hip joint promises a life-changing impact for individuals experiencing hip-related discomfort and limited mobility.1. Background and Market Need (100 words):Hip disorders and conditions affect millions of people worldwide, hindering their ability to walk, perform daily tasks, and maintain an active lifestyle. Traditional treatment options for hip-related ailments have often been invasive and have resulted in longer recovery times. Recognizing this critical need for an improved solution, [Company Name] prioritized research and development efforts into engineering a revolutionary orthotic hip joint.2. Revolutionary Features and Functionality (150 words):The orthotic hip joint prioritizes patient comfort, seamless movement, and long-lasting durability. Utilizing cutting-edge materials and incorporating high-tech features, this device offers unparalleled benefits. Its lightweight design, coupled with an adjustable range of motion, allows patients to perform a wide range of activities with ease. The orthosis accommodates the natural anatomical structure of the hip, aligning seamlessly with the body's movements and minimizing discomfort.Furthermore, the orthotic hip joint incorporates an innovative locking mechanism that ensures stability during weight-bearing activities. With this groundbreaking feature, patients can confidently trust the joint to provide reliable support and prevent any potential joint dislocations or instability. Additionally, advanced shock absorption technology enhances patient comfort and reduces impact during walking or other physical activities.3. Improved Quality of Life for Patients (150 words):By alleviating pain and restoring mobility, the orthotic hip joint significantly improves the quality of life for patients suffering from hip-related conditions. From participating in sports and recreational activities to undertaking routine tasks with ease, individuals can regain their independence and embrace an active lifestyle.Not only does the orthotic hip joint enable patients to experience substantial physical improvements, but it also offers psychological benefits. It empowers individuals, enhancing their self-confidence, and reducing any potential feelings of frustration or depression caused by limited mobility.4. The Manufacturing Process (100 words):[Company Name] employed extensive research and collaborated with leading orthopedic surgeons and engineers to develop this advanced hip joint. State-of-the-art manufacturing facilities and rigorous quality control measures ensure that each orthotic hip joint adheres to industry standards and surpasses patient expectations. The superior craftsmanship and precision employed in the manufacturing process contribute to the device's exceptional performance and longevity.5. Clinical Trials and Patient Testimonials (100 words):Before bringing the orthotic hip joint to market, [Company Name] conducted extensive clinical trials involving patients suffering from various hip disorders. The positive outcomes and favorable feedback from trial participants highlight the device's efficiency and role in transforming patients' lives. Many patients reported enhanced mobility, reduced pain, and an overall improvement in their quality of life.6. Future Developments and Price Accessibility (100 words):[Company Name] is committed to ongoing research and development, with a focus on refining the orthotic hip joint and expanding its use to a wider patient population. The company aims to make this life-changing technology accessible to all individuals in need, irrespective of their financial limitations. By employing cost-effective manufacturing processes and potential collaborations with insurance providers, [Company Name] endeavors to ensure that the orthotic hip joint becomes affordable and readily available to patients across the globe.Conclusion:With its breakthrough features, superior functionality, and significant impact on patients' lives, the orthotic hip joint developed by [Company Name] is set to revolutionize mobility. By addressing the limitations imposed by hip-related conditions, this innovative device enables patients to regain their freedom of movement, engage in physical activities, and greatly enhance their overall quality of life. With ongoing advancements and firm commitment to affordability, [Company Name] is positioning itself as a pioneer in orthopedic technology, providing a new lease of life to individuals suffering from hip disorders.

Tubular Medical Accessories for Amputation Stumps: Exploring the Benefits and Uses

for the disabled, amputees, prosthetic care, and medical socks.Stump socks have been around for quite some time and are an essential accessory for people who have experienced amputations. They are made to fit the unique shape of a residual limb, providing a snug and comfortable fit, helping to reduce swelling and preventing skin irritation.These medical socks are a critical aspect of prosthetic care, as they work to protect the sensitive skin on the residual limb from rubbing against the prosthetic's hard surface. By acting as a cushion between the prosthetic and the stump, stump socks help to prevent the development of painful pressure sores, which can cause immense discomfort and lead to further complications.In addition to providing comfort and protection, stump socks are also used to help manage residual limb volume, which can vary depending on factors such as changes in weight, activity level, or other medical conditions. This volume management is essential for ensuring a proper fit between the residual limb and the prosthetic, which is necessary for optimal mobility.Stump socks come in various materials, including cotton, wool, and synthetic fibers, and are often available in different thicknesses to cater to varying levels of sensitivity. They can be worn alone or combined with other prosthetic accessories to achieve the perfect fit.While stump socks are primarily used for prosthetic care, they can also be used as regular socks for people with limb differences that do not require prosthesis. For instance, people with partial foot amputations often wear stump socks to protect the sensitive areas of their feet and prevent skin irritation.There are numerous benefits associated with wearing stump socks. Firstly, they offer a layer of protection that helps to prevent skin damage. Secondly, stump socks help to regulate moisture, preventing the accumulation of sweat, which can cause skin irritation and bad odors. Thirdly, these socks help to manage residual limb volume, which is crucial to ensure optimal fit between the stump and the prosthetic.In conclusion, stump socks play a significant role in prosthetic care, helping to promote comfort, prevent skin irritation, manage residual limb volume, and prevent the development of pressure sores. They are available in different materials and thicknesses, making it easier for individuals to find the perfect fit. If you're an amputee or know someone who is, it's important to consider incorporating stump socks into your prosthetic care routine. In this way, you can benefit from their protective qualities and maintain healthy skin on your residual limb.

Discover the Versatility of 2mm Polypropylene Sheet for Your Project Needs

Polypropylene Sheet 2mm: A Versatile and Durable Solution for Industrial ApplicationsPolypropylene sheet 2mm is a versatile and durable solution for a variety of industrial applications. The material is known for its excellent chemical resistance, impact strength, and good stiffness. It is also lightweight, easy to fabricate, and available in a range of colors and finishes.Polypropylene sheet 2mm finds its use in various industries such as food packaging, automotive, construction, pharmaceuticals, and medical. The material is safe, non-toxic, and is compliant with FDA regulations, making it ideal for use as food containers, trays, and packaging. Its excellent chemical resistance makes it perfect for use in the automotive industry, where it is used as a base material for gas tanks, battery cases and interior components.The construction industry also relies heavily on polypropylene sheet 2mm for its lightweight and durable characteristics, making it ideal for use in roofing, cladding, and insulation. The material is also popular in the medical and pharmaceutical industry, where it is used as sterile packaging materials, laboratory equipment, medical implants, and disposable surgical instruments.Polypropylene sheet 2mm can be manufactured in different colors and finishes, providing designers with a wide range of options to choose from. The manufacturing process also allows the material to be produced in various thicknesses, consequently offering a flexible range of applications depending on the desired mechanical properties.This material is not only versatile but also environmentally friendly. Its lightweight and easy-to-transport properties reduce energy consumption and transportation costs, making it a popular choice for industries seeking to reduce their carbon footprint.Polypropylene sheet 2mm is also recyclable and can be transformed into a range of products such as brooms, car parts, and waste bins, further reducing its environmental impact. It can also be incinerated without emitting harmful toxins into the atmosphere.However, not all polypropylene sheets manufacturers are created equal. When choosing a supplier for your polypropylene sheet 2mm requirements, it is crucial to consider a company's reputation, experience, and technical expertise.{Company name} is one such company with over {number of years} years of experience in the manufacturing of polypropylene sheets. With an excellent reputation for quality and reliability, it is a go-to supplier for industries seeking high-quality and cost-effective solutions.{Company name} is committed to sustainable business practices, with a focus on reducing environmental impact while providing quality products. The company's state-of-the-art manufacturing facility and technical expertise make it possible to produce a wide range of custom polypropylene sheets, tailor-made to meet the specific requirements of each client.{Company name} takes pride in its excellent customer service, with a team of professionals dedicated to ensuring that clients' needs are met, from initial consultation to delivery. Customers can rely on the company's fast response times, competitive pricing, and timely delivery schedules.In conclusion, polypropylene sheet 2mm is a versatile and durable solution for a range of industrial applications. With its excellent chemical resistance, good stiffness, and impact strength properties, it is a popular choice in various industries. When choosing a supplier for your polypropylene sheet 2mm needs, it is crucial to consider a company's reputation, experience, and technical expertise. {Company name} is a leading supplier of high-quality polypropylene sheets with over {number of years} years of experience and an excellent reputation for quality and reliability. With a state-of-the-art manufacturing facility and commitment to sustainable business practices, clients can expect quality products, fast response times, and excellent customer service.

Yes, it is possible to assign custom attributes to symbols in Mathematica and check them later. In Mathematica, you can use the `SetAttributes` function to assign attributes to symbols. However, attributes must be predefined or built-in attributes in Mathematica, and you cannot assign completely custom attributes. In the given example, the code `SetAttributes[a, b]` is attempting to assign the attribute `"b"` to the symbol `a`. Since `"b"` is not a known or built-in attribute in Mathematica, it results in an error message: `Attributes::attnf: b is not a known attribute.` To remove a brand name from an SEO title, you would need to provide specific information about the brand name and the desired modifications to the title.

Title: Custom Attributes in Mathematica: Empowering Symbol Manipulation through Personalized MetadataIntroduction:In the realm of symbolic mathematics, Mathematica stands as a powerful tool for computation, analysis, and modeling. Its versatility allows users to manipulate symbols and expressions effectively. However, sometimes standard attributes may not fully capture the specific requirements of a problem. This sparks the need for custom attributes, enabling users to assign personalized metadata to symbols for later reference and enhanced manipulations.Custom Attributes: Expanding Symbolic Manipulation HorizonsTraditionally, Mathematica has provided a wide range of predefined attributes such as "Listable," "Protected," and "NumericFunction." These attributes define properties and behaviors for symbols, enabling various optimizations and error checking during computations. However, users often encounter situations where the standard set of attributes does not meet their needs.To address this limitation, Mathematica introduced the concept of custom attributes, empowering users to create and assign their own attributes to symbols. These custom attributes can capture specific properties, behavior patterns, or additional information related to a symbol, creating a more tailored environment for symbolic manipulation.Assigning Custom Attributes:To assign a custom attribute, users utilize the SetAttributes function, specifying the symbol and the desired attribute as arguments. For example:SetAttributes[a, b]Here, we attempt to assign the "b" attribute to symbol "a." However, if "b" is not a predefined attribute, Mathematica raises an Attributes::attnf error, indicating that "b" is not a known attribute. This feedback prompts users to either remove the nonexistent attribute or define it.Custom as Your Dimension:In today's rapidly evolving technological landscape, businesses are increasingly seeking customization and flexibility to adapt to unique challenges. Mathematica's support for custom attributes aligns perfectly with these demands. Users can now leverage this feature to define attributes that align with their specific domain or project requirements.Imagine a scenario where you are working on a complex engineering project. You can create custom attributes like "Dimension" or "MaterialProperty" and assign them to symbols representing physical quantities or properties. Later, when performing calculations, you can easily check these custom attributes to ensure consistency and perform specialized operations.Expanding Symbol Manipulation Possibilities:By enabling the assignment of custom attributes, Mathematica revolutionizes the possibilities for symbolic manipulation. Besides capturing specific properties, custom attributes also streamline code readability and maintainability. With personalized metadata attached to symbols, users can better understand the context or intention of their code, reducing confusion and ensuring more reliable computations.Conclusion:Mathematica continues to empower users by offering the flexibility to extend its functionality beyond standard attributes. The introduction of custom attributes brings a new dimension to the symbolic manipulation landscape, allowing users to effortlessly assign tailored metadata to symbols. By leveraging custom attributes, users unlock a realm of enhanced manipulation, improved code structure, and increased understanding of complex mathematical models. As users embrace this powerful feature, Mathematica solidifies its position as a leading tool for symbolic computations.

Discover the Benefits of Expanded Polypropylene Sheets for Various Applications

Title: Revolutionary Expanded Polypropylene Sheet: Advancing Industry StandardsIntroduction: In a constant effort to push the boundaries of material technology, [Company Name] has recently announced the development of an innovative Expanded Polypropylene (EPP) sheet. This breakthrough in material science promises to revolutionize various industries, from automotive to packaging, with its exceptional properties and versatile applications. With sustainability at the forefront, [Company Name] aims to introduce a game-changing material that not only meets industry standards but also aligns with global environmental goals. The Expanded Polypropylene Sheet:The newly developed EPP sheet by [Company Name] offers a wide range of advantages over traditional materials. The unique characteristics of the sheet stem from its closed-cell structure, which allows for a lightweight composition while maintaining strength and durability. The incredible versatility of the EPP sheet allows it to be molded into various shapes and sizes, catering to the specific requirements of different industries. One of the key advantages of this EPP sheet is its remarkable energy absorption capabilities. Due to its cellular structure, the sheet can withstand impact and resist deformation, providing enhanced protection for products and ensuring safety in critical applications. Industries such as automotive, transportation, and packaging can greatly benefit from this exceptional property, reducing the risk of damage to goods and improving safety standards.Moreover, the EPP sheet possesses excellent thermal insulation properties, making it highly suitable for temperature-sensitive applications. Industries such as construction and refrigeration can leverage this feature to enhance energy efficiency, reduce carbon emissions, and create more sustainable solutions.The environmentally friendly nature of the EPP sheet is another noteworthy aspect. The material is 100% recyclable, minimizing waste and reducing the carbon footprint of industries that incorporate it into their products. This aligns with [Company Name]'s commitment to sustainable manufacturing practices and contributes to the overall goal of creating a greener future. Applications in Various Industries:Automotive Industry: With its exceptional energy absorption properties, the EPP sheet offers immense potential in the automotive industry. Car manufacturers can incorporate the sheet into bumpers and body panels, enhancing crash safety and reducing vehicle weight. Additionally, its thermal insulation capabilities make the EPP sheet ideal for soundproofing and heat retention, further improving the overall driving experience.Packaging Industry: The EPP sheet's shock-absorbing characteristics make it a valuable asset in the packaging industry. By utilizing this material, delicate products can be safely transported, reducing damage and saving costs associated with product replacement. The sheet's lightweight nature also contributes to cost-effective shipping, benefiting businesses across the supply chain.Construction Industry: The EPP sheet's thermal insulation properties find significant application in the construction industry. As an eco-friendly alternative to traditional materials, it can be utilized in roofing, insulation panels, and interior design elements, providing energy-efficient solutions and reducing the dependency on unsustainable materials.Medical Industry: In the medical sector, the EPP sheet's lightweight composition and resistance to sterilization processes make it an ideal material for medical equipment and devices. Its ability to absorb impact enhances the safety of fragile medical instruments during transport and storage, ensuring their integrity and, ultimately, benefiting patient care.Conclusion:The introduction of [Company Name]'s revolutionary Expanded Polypropylene sheet marks a significant milestone in materials science. With its exceptional properties, including energy absorption, thermal insulation, and environmental sustainability, this sheet is poised to transform various industries. Through its wide range of applications, the EPP sheet promises to enhance safety standards, enable sustainable solutions, and drive innovation across sectors. As [Company Name] continues to innovate, it is paving the way for a more efficient, environmentally conscious future.

4x8 Polypropylene Sheets: A Versatile Solution for Various Applications

Polypropylene Sheets: A Versatile Solution for Your Industrial NeedsIn today's ever-evolving industrial landscape, companies are constantly seeking innovative solutions to cater to their unique requirements. One such solution that has gained significant popularity in recent years is Polypropylene Sheets. These lightweight, durable, and versatile sheets have become a go-to choice for various industries, thanks to their exceptional properties and affordability.Polypropylene, a thermoplastic polymer, is the main component of these sheets. It exhibits excellent chemical resistance, making it suitable for applications where exposure to chemicals is inevitable. Additionally, it boasts high tensile strength, stiffness, and dimensional stability, ensuring that the sheets retain their structure even under heavy loads or extreme temperatures.The 4x8 dimension of the Polypropylene Sheets adds to their versatility, making them ideal for a wide range of applications. Whether you need durable packaging materials, cutting boards, signage, or even automotive parts, these sheets can be easily shaped, folded, or cut to meet your specific requirements. Their lightweight nature also makes them an excellent choice for industries that prioritize weight reduction, such as the aerospace and automotive sectors.The sheets' exceptional electrical insulation properties make them an ideal choice for applications requiring electrical components or insulating barriers. They are non-conductive, meaning they effectively prevent the flow of electricity and reduce the risk of any unexpected electrical hazards. This makes Polypropylene Sheets a popular choice for manufacturing electrical enclosures, switchboards, and electrical insulation components.Due to their outstanding resistance to moisture, Polypropylene Sheets are also widely used in the construction industry. They can be utilized as a vapor barrier in buildings, preventing the infiltration of moisture and protecting the structure from potential damage. Moreover, their resistance to mold and mildew makes them an excellent choice for areas with high humidity, ensuring the longevity and integrity of the construction project.Another crucial advantage of Polypropylene Sheets is their recyclability and environmental friendliness. In today's world, where sustainability is at the forefront of every industry, these sheets offer a greener alternative. They can be easily recycled and reused, minimizing the impact on our planet and reducing the need for virgin materials.One leading company at the forefront of producing high-quality Polypropylene Sheets is {}. With a solid reputation and years of experience in the industry, {} has become a trusted name. Their state-of-the-art manufacturing facilities and commitment to quality ensure that their sheets meet the highest standards.{} employs a team of skilled professionals who thoroughly understand the unique requirements of their customers. They work closely with clients in various industries to develop customized solutions that cater to their specific needs. By leveraging the advanced techniques and equipment at their disposal, {} delivers top-notch Polypropylene Sheets that not only meet but exceed customer expectations.The company's dedication to innovation and continuous improvement ensures that their products stay ahead of the competition. They constantly invest in research and development to explore new applications and improve the overall quality and performance of their Polypropylene Sheets. This commitment to excellence has earned them a loyal customer base and accolades in the industry.In conclusion, Polypropylene Sheets have emerged as a versatile and reliable solution for a wide range of industrial applications. Their exceptional properties, including chemical resistance, dimensional stability, and electrical insulation, make them an ideal choice for industries ranging from packaging and construction to automotive and electrical. Companies like {} play a critical role in delivering high-quality Polypropylene Sheets that meet the specific needs of their customers. As businesses continue to evolve, these innovative sheets will undoubtedly remain a go-to choice for industries worldwide.